Dzignstone®

FAQ

No, the Dzignstone shower panels are already 100% waterproof.

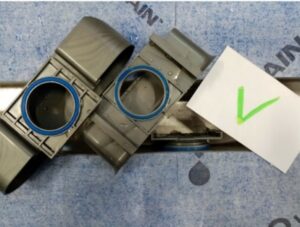

First and foremost, check the sealing rings on the siphon.

The outer sealing ring of the siphon must be round, and the inner sealing ring must be flat. If both rings are flat, all you have to do is tell your dealer. You will receive a new siphon with the correct sealing rings without any quibble. By replacing your old siphon with a new one, this should rule out the possibility of unpleasant smells. The siphon refills with water after every wash, and there is no smell.

Silicone sealant completely around the drain without interruption?

Check whether the water level at the siphon is sufficiently filled. If your siphon is half submerged, fill your bath, another sink or flush the toilet.

Check that the siphon is not installed upside down, is the word ‘TOP’ visible?

Check that the siphon is not installed crookedly.

Inner screw not tight enough.

Click for video for correct placement of the inner screw.

Click for the video for wrong placement of the inner screw.

Clear your hair strainer.

Clear your strainer weekly.

Floating siphon.

This problem only occurs with the first generation of I-Drain with the thin O-ring. The current siphons are fitted with a thick modified O-ring. In such case, we simply send a new adapted siphon under service.

This problem only occurs with the first generation of I-Drain with the thin O-ring. The current siphons are fitted with a thick modified O-ring. In such case, we simply send a new adapted siphon under service. (see “What to do if there is an unpleasant smell”).

Don’t jump to the conclusion that something is wrong with the I-Drain siphon.

It is probably a ventilation problem in your piping!

Thanks to our years of experience, we know that most drainage problems are due to ventilation problems in the pipes.

You can perform a simple test! If the water runs away smoothly if you remove the siphon from the drain, then you can be almost certain that you are dealing with a ventilation problem.

In the event of a ventilation problem, an air bubble is trapped in a bend in the pipework. This air bubble is reducing the drainage capacity, because the pipe cannot fill completely with water. A half-full pipe only drains away half as much water. In a perfectly ventilated pipe system, the air bubble always has the possibility of escaping. In a case of poor ventilation, it has nowhere to go.

Below, you will find a summary of the ideal composition of your pipe system and of a number of common installation errors that can cause poor ventilation.

How can I solve this ventilation problem:

The only solution for the ventilation problem is to install another siphon (with a goose-neck) somewhere else in the home (e.g. in the cellar). It is advisable to contact the installer directly about this. He will examine the problem with you, and advise you based on his experience.

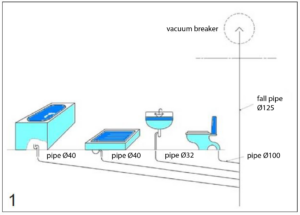

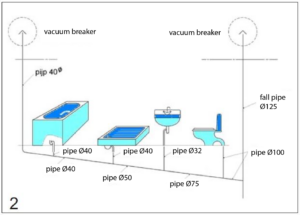

Figure 1 and 2 show how the house sewerage system should be ventilated correctly.

Figure 1: individually

All drain pipes are connected separately to the fall pipe / standpipe.

Figure 2: Collector.

It is more usual, as well as saving costs and space, for several drain pipes to be connected to the collector pipe (with ventilation) and that this collector is connected to the fall pipe/standpipe. Of course, the collector also has to be ventilated by a ventilation pipe.

Combinations of both methods are possible. For optimum drainage, it is recommended to take the following points into account:

The connection of the toilet:

For optimum drainage, it is best to connect the toilet separately to the main fall pipe, preferably with a 45° bend instead of a 90° bend (if necessary, make two 45° bends).

Mount 45° bend directly on the external screw part

Normally, the socket must be attached to the external screw part of the siphon in order to make the connection to the drain. In some cases it may happen that there is no space to place a sleeve and that you wish to work directly with a bend. A 45° bend can be mounted directly on the outer screw part. This will also not pose a problem for the discharge capacity (depending on the capacity of the supply). One should always take into account the more one is going to work with bends, the less drainage capacity one will have. If a bend of 45° is to be placed directly on the external screw part, we must work with a rubber seal and the whole may not be glued. Because when tightening, you have to put force on this and if you are going to glue the whole, there is a chance that it will still come loose. Therefore, always work with a rubber seal, so that the whole can be tightened properly and that it is secured.

Connection of both a shower and a bath:

When emptying the bath, it sometimes happens that the bathwater flows into the shower via the shower drain, causing it to overflow. This phenomenon occurs if the diameter of the collector pipe is too small. The shower and the bath then act as communicating vessels, which always try to maintain the same water level. In that case, you would be well advised to connect the shower separately to the main fall pipe.

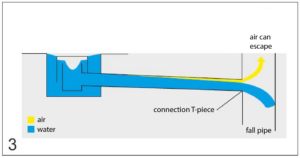

The connection of the collector to the fall pipe:

It is recommended to use a T-connector to connect the pipes to the main fall pipe, as you can see in Figure 3. Via the T-connector, the air can escape from the pipe and optimal drainage capacity can be guaranteed for the pipe.

Incorporation of bends > transition from 40mm to 50mm:

In the horizontal area, it is advisable not to incorporate any bends. Every bend increases the risk of air bubbles that stay in the pipe. If you do incorporate them, then fit a transition from 40 mm to 50 mm and even install the bend with a 50 mm diameter pipe.

Min. length widening from 40 to 50mm

Should always be done after max. 1 meter or before a bend. There is no minimum length because you can actually switch directly to diameter 50, but then you have to work with an eccentric sleeve and never glue one with a rubber sealing ring. Because when tightening, you have to put force on this and if you are going to glue the whole, there is a chance that it will still come loose. Therefore, always work with a rubber seal, so that the whole can be tightened properly and that it is secured. But you have to see because you switch directly at the beginning to diameter 50, the sleeve will also rise a few mm – so be careful with chapping – hence the eccentric sleeve. And it is possible to work with bends, but it is always best to work with bends of 45° instead of 90° (due to drainage cap.). So theoretically it is best to only go from 40 to 50 after 25 cm.

Of course, the entire piping must always be in a downward gradient.

Look at “Wat do I do if the water stops running away”.

- Solvents such as acetone…

- Chemical products such as grout residue remover, drain unblockers, …